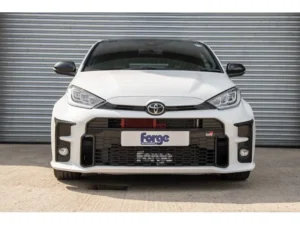

Forge Motorsport Intercooler Toyota Yaris GR 1.6

$1,680.00

Overview

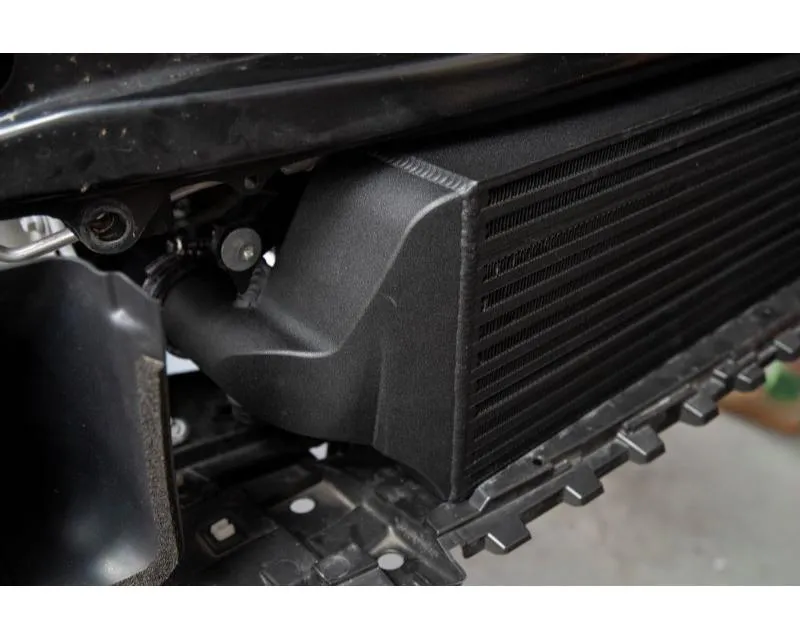

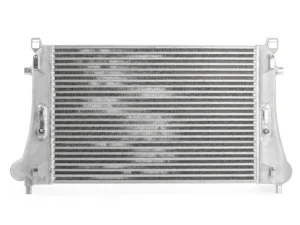

Using a combination of scanning software and traditional measuring methods, the design was created. This was then fine tuned by our computational fluid dynamics (CFD) team, and the end tanks were initially created by 3D printers. We then alloy cast our first prototypes from our 3D prints using a sand casting technique and started the testing procedure on several types of intercooler cores.

The first iteration fitted the vehicle perfectly, however, our technicians and engineers felt the inlet and outlet should be enlarged along with providing the end user with the necessary boost pipes to ensure flow was maximized on the Toyota`s GR 3 cylinder engine.

Before getting to work on the dyno, we spec’d three different type of cores; one of these being bar and plate and two being a tube and fin construction – with all three cores having different internal and external fin pitches and configurations. We then welded the test parts ready for testing along with fabricating an internal baffle to the inlet (hot side) of the end tank. This is to ensure, from our CFD research, that the total volume of the core internal is utilised for optimum performance.

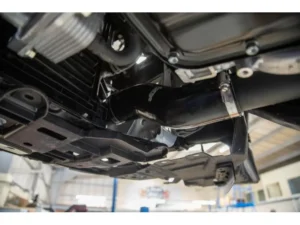

Compared to the OEM intercooler, the improved Forge product has a surface area increase of over 42% and an internal volume increase of over 100% as well as Gains of more than 10bhp and 10 lbs/ft. These gains can be even higher depending on your vehicles state of tune and complementing performance products like the turbo inlet adaptor and the inlet duct. As the hot and cold side, inlet and outlet, have been increased to 60mm, we have included within the intercooler kit all the necessary silicone hoses and hardware to complete the installation and connect to the OEM parts.

The Forge Motorsport intercooler is a perfect performance enhancing product that fits directly to the OEM mounting points, making for an easy install, in a relatively short period of time. No cutting of any components are needed, making the installation reversible if the vehicle needs to be returned to stock at any time in the future. The core and end tanks are finished in our black textured anti corrosion coating that also aids with its thermal properties and keeps the product looking that bit more stealthy or OEM+.

The Forge Motorsport lifetime warranty on all hardware products shows the trust we have in the quality of our products while they are being enjoyed on your pride and joy.

Why do we test different cores?

Here at Forge Motorsport, when developing an intercooler, we will test several different cores for each application. For example, a bar and plate style core, a tube and fin style core along with different fin pitches and heights e.g. 22 fins per inch or 17 fins per inch, as well as changing the internal fin pitches/shapes and density within the tube enabling to fine tune the amount of pressure drop the intercooler produces.

Pressure drop is not always a bad thing, as our testing and research has proven on various projects. This is because the pressurized air velocity is being stalled by the pressure drop within the cooler thus allowing more time to cool the air within the cooler itself, as air passes through the non-pressurized face of the core that is open to the atmosphere. Too much pressure drop can of course have a problem on the higher performance engines as the intercooler reaches its maximum efficiency the turbo has to work a lot harder to force the air through the core. This in turn creates higher inlet air temps (IAT’s) due to the turbo creating more heat as it is over stressed and worked harder.

Having no pressure drop can also prove to be inefficient as the cooler will not lower the charge temperature again resulting in higher inlet air temperatures.

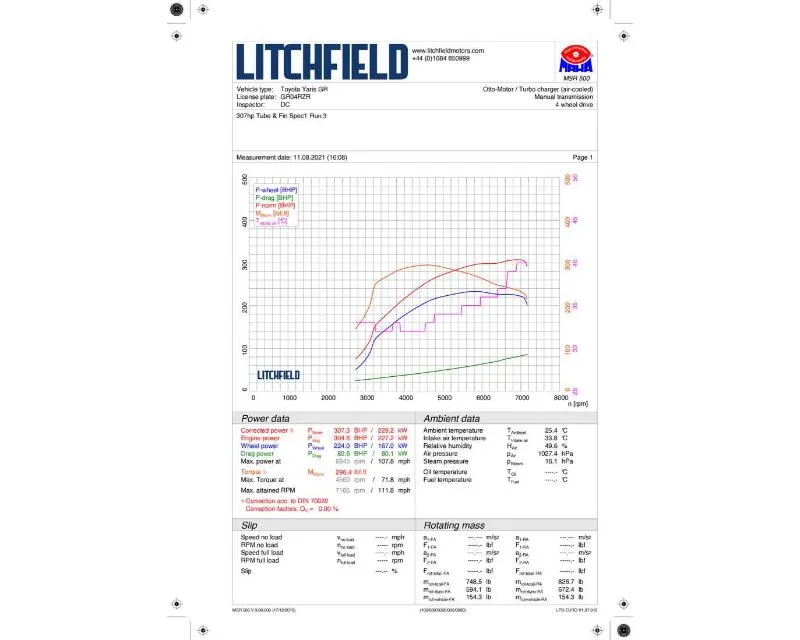

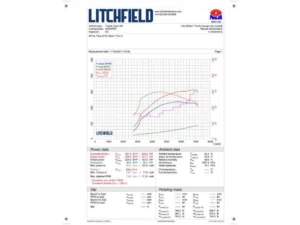

Dyno Results

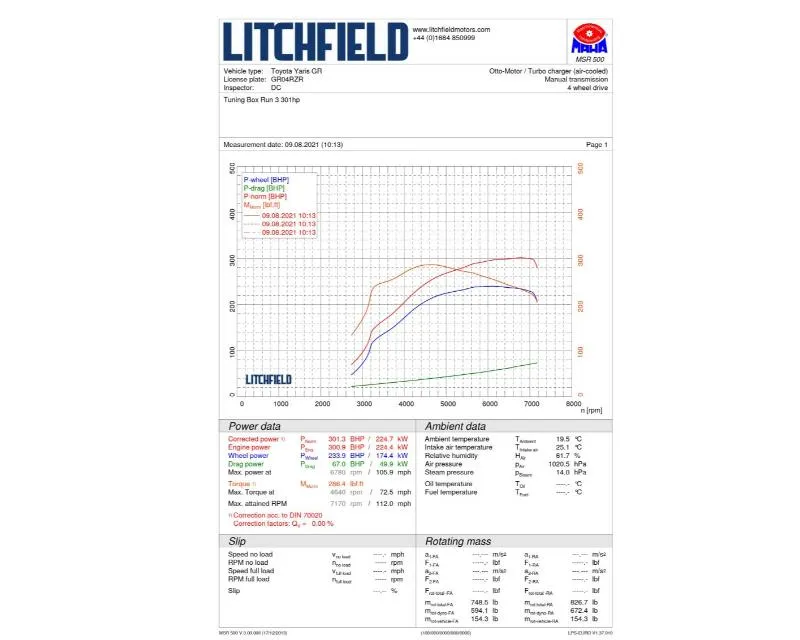

Testing was completed on Litchfield’s Maha dyno, manufactured by the same people who currently supply BMW M sport and Mercedes Benz for all their engine calibration and dyno testing.

The vehicle used for testing had a full turbo back exhaust along with a DT UK Tuning box. Our first run with an ambient air temperature of 19.5°C, gave results of 301.3 BHP and 286.4 lbs/ft of torque. Later after the 3rd pull on the dyno, the inlet air temp quickly increased to nearly 58°C, with the BHP and torque both decreasing to 295bhp and 278 ft/lbs.

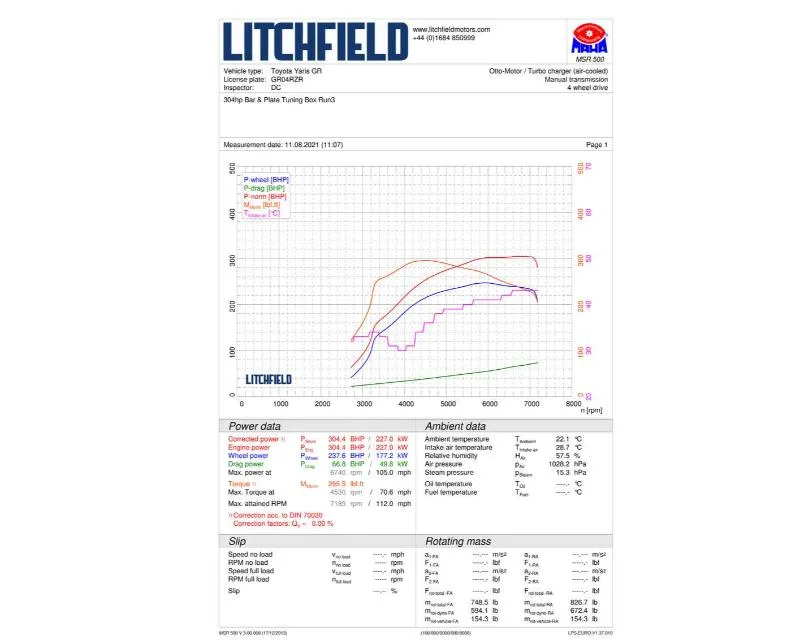

Our first test Forge intercooler was on our bar and plate design core. The weather on this day was hotter with an ambient dyno cell temperature of 22.1°C. On our third dyno pull on the bar and plate design, the intercooler yields were 304.4 BHP and 295.5 lbs/ft of torque as shown in the graph below. The inlet air temp is highlighted in pink, and shows the intake air temperature reduced to 44°C. So we had achieved a good gain in torque and a reduction in inlet air temps when the testing environment was actually hotter.

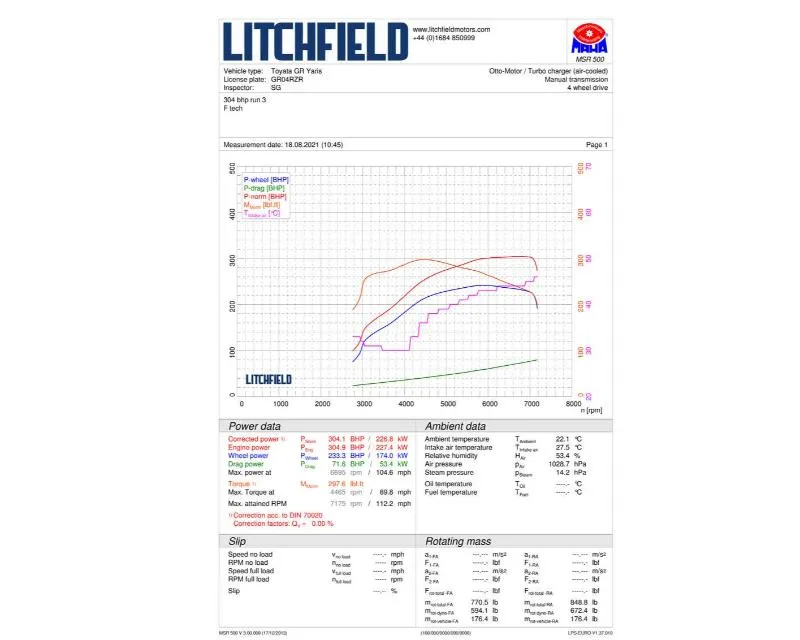

For our second test we used a very high density external fin pitch core with a tube and fin design. These cores are typically lighter than the bar and plate counterparts. Again the dyno cell ambient air temps here higher than when we tested the OEM intercooler. This time the results showed we had again achieved an impressive reduction in IAT’s with power figures resulting in 304.1 BHP and 297.6 lbs/ft of torque, inlet air temps on the third pull were no higher than 46°C.

Our third and final core to test had a slightly smaller thickness than the two previous variants resulting in a slightly smaller volume, and with the hottest test day so far of all the intercoolers in question at 25.4°C within the dyno cell, we were not confident we could improve on the previous results. The results however speak for themselves. On the third pull inlet air temps stayed at a steady 40°C and with the highest BHP gain at 307.3 BHP, and torque peaking at 296.4 lbs/ft

We had found our winning formula. At this point though we did not simply stop; we repeated our testing to ensure our results were true and checked all our test vehicles sensor data to ensure there were no negative effects.

Features:

- Gains of 10bhp and 10lbft

- Temperature drops of up to 20°C

- Reduced turbo lag, increased response

- Greater overall surface area for greater heat dissipation

- Utilising a race specification tube and fin construction air core

- High flow cast end tanks ensuring optimum air transition for cooling efficiency

- Dyno proven horsepower and torque gains

- A smoother power curve

- Volumetric increase of more than 100%, without additional lag

- Frontal area increase of over 40%

- Includes necessary hardware and instructions for installation

- Lifetime warranty

Install Instructions:

- For Instructions CLICK HERE

Fitment:

- Toyota Yaris GR 1.6

Note:

- In line with our policy to constantly review, revise, and improve our product range, the appearance of the product you receive may differ from the one advertised.

⚠ WARNING:

Cancer and Reproductive Harm

https://www.P65Warnings.ca.gov

Fitment

|

Make Vehicle |

Model | Year |

|---|---|---|

|

2020-2023 Toyota Yaris |

Yaris | 2020-2023 |

About Brand

About Forge Motorsport

Forge Motorsport is a world leader in aftermarket car parts, that includes actuators, intercoolers, blow-off valves, fabricated alloy tanks, big brake kits, wastegates, and silicone hoses. The company was founded in 1996 with the simple principles of innovation, crafty designs, and high-quality manufacturing. The company is comprised of passionate petrolheads who are dedicated to designing and developing vehicle-specific performance parts for OEM And turbocharged applications.

If you are looking to get the most out of your Audi, BMW, or Volkswagen’s performance, you can count on Forge Motorsport in the United Kingdom. Each individual Forge branded product proudly states “Made In Great Britain.” Forge Motorsport is based out of Gloucester, England, where its headquarters and manufacturing plants produce its ever-growing lineup of products. The company also has a full sales and distribution facility in Orlando, Florida (Forge USA) and one in Taichung, Taiwan (Forge Asia)

Forge Motorsport’s Manufacturing Process

All Forge Motorsport products are manufactured in-house in its state-of-the-art CNC machine shop by a team of highly skilled engineers and fabricators. All Forge production is controlled by the international ISO 9002 standard for manufacturing design and development. Billet parts are machined to the strictest tolerances and undergo exhaustive testing and inspection before they are released. All welding is also done in-house, by Forge’s in-house craftsmen, and boasts unsurpassed quality and robotic-like precision. Not only do Forge Motorsport’s products look great but they also perform second to none. What’s more, all Forge products are guaranteed for life and backed by Forge’s “No Hassle” service promise.

With immense knowledge at its disposal, Forge is honored to supply the leading names and race teams in the world of motorsport, including F1, Rally X, WRC, and Le Mans, as well as several OEM manufacturers.

Forge Motorsport at Vivid Racing

Vivid Racing carries a wide array of Forge Motorsport parts, including intercoolers, big brake kits, blow-off valves, wheel spacers, wastegates, turbo hoses, intakes, radiators, and much more! If you cannot find a specific item above or have any general questions, please do not hesitate to call our expert sales team at (480) 428-0879. We are here to make the buying experience a simple and pleasant one.

Warranty

Forge Motorsport are one of the largest manufacturers of aftermarket turbo accessories, bringing cutting edge design and the highest quality to our product line, we strive every day to bring excellence to our customers. Sometimes, things can go wrong and we want YOU the customer to know you will be looked after beyond any level of customer service you have ever experienced before. With that in mind, the Forge Motorsport (Limited) Lifetime Warranty covers only products that have been purchased directly from us, or one of our authorised distributors/dealers.

If your Forge product fails or breaks due to a manufacturing issue or defect, we will repair or replace, at no charge to the customer at our discretion. This service will only be carried out IF the Forge product is still in its original unchanged design condition and the item/product has not been modified or changed in anyway. The Forge Motorsport (Limited) Lifetime Warranty will not cover any damage or failure caused by; improper or incorrect installation, normal wear and tear, finished colour/aesthetic appearance of the product, the normal degradation of material over time, or if the product has been exposed to the use of any Traffic Film Remover or alternative acidic cleaner (commonly used in hand car washes).

The warranty will also be invalid if the Forge product has not been fitted to correct applications that it was designed for. Any damage to Forge products that occur outside of the warranty can be sent in for evaluation and a quotation to repair or replace said product along with a return shipping fee. The Forge products that are covered by our (Limited) Lifetime Warranty are to the original purchaser or owner of the Forge item for the lifetime of that said product only. The warranty policy is NOT TRANSFEREABLE However given the quality of the product that Forge manufacture we are confident of great longevity of your “Engineered for Performance†Forge part.

For any warranty claim or query please contact our Forge Motorsport sales team in your region or country. www.forgemotorsport.co.uk UK & EU www.forgemotorsport.com USA and South America www.forgemotorsport.asia Asia

Any shipping or returns to Forge Motorsport must be insured, pre-paid and include a Forge Motorsport Goods Returns Form and a copy of the original invoice or proof of purchase to allow us to better serve you. The terms and conditions to the Forge Motorsport (Limited) Lifetime Warranty policy are subject to change at any time without notice.

Please note, Pipercross filters are excluded from our Lifetime Warranty

Reviews

There are no reviews yet.